Unlocking the secrets of solder mask: the unrecognized hero of PCB manufacturing

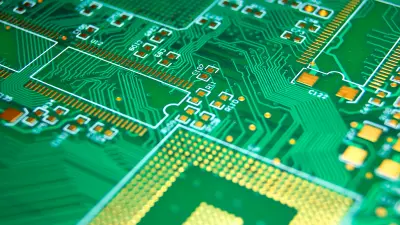

Solder masks are the champions of Printed Circuit Board (PCB) production, providing durability, functionality, and visual appeal for electronics. A crucial yet often overlooked aspect of modern electronics manufacturing is the relationship between solder masks and PCBs. Solder mask technology has evolved to meet the increasing demands of the electronics industry, including higher circuit densities, improved thermal management, and enhanced reliability.

What is a solder mask and why does it matter?

A solder mask, often referred to as solder resist, is a vital layer of protective material applied to the surface of a printed circuit board. This mask is typically made from a polymer-based compound and serves to insulate the copper traces and surfaces on the PCB, preventing short circuits and protecting against environmental damage.

The primary purpose of a solder mask is to ensure that the solder only adheres to the designated pads and traces during the soldering process. This precision is crucial for the functionality and reliability of electronic devices, as it prevents unintended electrical connections and reduces the risk of component failures.

In general, there are 2 types of solder masks:

- Permanent: Solder mask which is permanently applied and not removable after the application process is completed.

- Temporary: Solder mask which is applied and can be peeled off after soldering or assembly, leaving the PCB ready for final use or additional manufacturing steps.

Benefits of solder masks in PCB manufacturing

- Protection: prevents oxidation and corrosion of the copper tracks which leads to a longer service life of the PCB.

- Functionality: reduces solder bridges and short circuit risks.

- Protection against contamination: the solder resist ensures that no dirt or foreign material can penetrate between the conductor tracks during production. This reduces the risk of short circuits.

- Increased mechanical resistance: a solder resist with sufficient thickness increases the robustness of the PCB against mechanical impacts such as knocks and scratches during its manufacture and use.

- Color selection for specific applications: solder mask color can provide functional benefits, such as using white solder mask in LED applications for higher light reflection and a cleaner white, or black matte as opposite – to decrease reflection where this is functional requirement.

Different types of solder masks: which one is right for your product?

There are several types of solder masks available, each with unique properties suited to different applications. The most common types include Liquid Photo Imageable (LPI) solder masks, dry film solder masks, and epoxy liquid solder masks.

LPI solder masks are widely used due to their high precision and ability to produce fine features. Dry film solder masks are preferred for their ease of application and consistency in thickness, making them ideal for high-volume production. Epoxy liquid solder masks, on the other hand, are cost-effective and provide excellent coverage, but they may not be suitable for intricate designs.

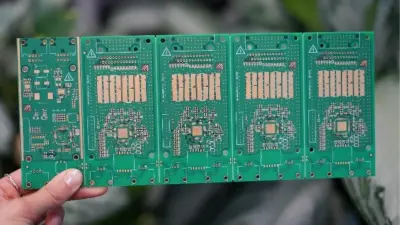

Applying solder masks: a step-by-step guide

Applying a solder mask involves several critical steps to ensure optimal coverage and performance.

- First, the PCB surface is thoroughly cleaned to remove any contaminants.

- The first step is followed by the application of the solder mask material, which can be done through screen printing, curtain coating, or spray coating.

- Once applied, the solder mask undergoes a curing process, typically using UV light or heat, to harden the material.

- Finally, the mask is developed, where unexposed areas are removed, leaving only the desired pattern on the PCB. This process requires precision and attention to detail to ensure the solder mask adheres correctly and provides the necessary protection.

Future trends: innovations in solder mask technology

The field of solder mask technology is continuously evolving, with new materials and application techniques being developed to meet the demands of modern electronics. Innovations such as flexible solder masks for use in flexible PCBs and advanced UV curable masks are revolutionizing industry. As technology advances, we can expect to see more robust and versatile solder mask solutions that enhance the performance and reliability of electronic devices.

Enhancing everyday electronics

Solder masks play a pivotal role in enhancing the performance and reliability of everyday electronics. From household appliances to automotive systems, solder masks ensure that devices function correctly and have a longer lifespan.

By preventing short circuits and protecting the PCB against external damage, solder masks contribute to the overall quality and dependability of consumer electronics. This, in turn, leads to fewer product failures and a better user experience.

Criteria for acceptance

IPC-6012 and IPC-A-600 are the most crucial standards for rigid PCBs with solder resist. The fundamental specifications for PCB processing and quality are outlined in these standards. The solder resist itself is subject to the IPC-SM-840 standard. It distinguishes between two kinds of solder resists and stipulates a minimum dielectric strength of 500V, among other things:

IPC-6012 and IPC-A-600 are the most crucial standards for rigid PCBs with solder resist. The fundamental specifications for PCB processing and quality are outlined in these standards.

The solder resist itself is subject to the IPC-SM-840 standard. It distinguishes between two kinds of solder resists and stipulates a minimum dielectric strength of 500V, among other things:

- Class T (telecommunications)

- Class H (high reliability)

The Class T and UL94 are the minimum requirements for solder resists. Class H also corresponds to Class 3 according to IPC-6012.